More than 30 years of experience and process knowledge from more than 100 foundries are part of our FRP system. In contrast to common ERP systems, the focus is on the entire path to the raw casting part including all necessary finishing steps. Thereby, FRP.OPTI consistently covers the entire process from the request to the delivery of the ready-to-ship part without any compromises.

Every foundry is different and that is why the different casting methods and material types are considered in the FRP standard.

Convince yourself of the performance of our FRP solution and also benefit from the "more" of information, the efficiency and the effectiveness that you will receive with FRP.OPTI.

Foundry Knowledge - Cast in Software by RGU.

Overview of FRP.OPTI

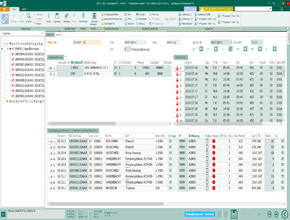

Planning

- Integrated work plan and parts list as a universal resource plan

- Simple, fast and accurate calculation across all production stages

- Create a new part in just a few minutes by duplicating and modifying resource plans

- Similarity search and extensive search functions

- Integrated material database

- Inquiry scheduling taking into account the complete scheduling framework

- Automatic Material Requirements Analysis

- Workflow- and release-controlled cross-departmental work

Reporting

- Integrated web-based FIS (Foundry Information System) as an continuous information system for all product and production-relevant data

- Management information for decision makers

- Extensive standard reports and real-time evaluations

- Visual planning via utilization and capacity cockpits

Production

- Illustration of all hand and machine forming processes

- Automatic scheduling across all production stages, taking into account capacities and bottlenecks (MRP II run)

- Flexible, scalable feedback chains in production

- Task-driven management of all tools and patterns for moulds and cores

- Integrated inspection planning and certificate generation

- Daily or shift-accurate detail planning via add-ons

- Synchronized processes through seamless linking of the foundry-specific modules

Rework, Lock Stock, Reject

- Separate recording of faultless goods, blocked goods and rejects

- Reasons for rejection and dedicated rejection statistics can be chosen as needed

- Triggering of rework order with additional information and reasons for rejections

Confirmation management

- Single or collective confirmation

- Manual confirmation or by means of production data acquisition or machine data acquisition

- Individually customizable reporting masks

- Incentive pay detection

Logistics, Shipping

- Customer-specific packaging regulations

- Packaging bills of materials

- Automated load list creation

- Automated creation of goods tags, forwarding orders, delivery notes

ESP, enhanced workbench

- Easy integration of external work sequences

- Automatic accompanying document creation

- Control of goods received via barcode

- Goods receipt document with invoice verification

- External stock overview

- Provision, manual or automatic.

- Price, quantity scales and additional services

Purchasing

In purchasing, you make the procurement of your company clear and efficient. The master data stores all the information on suppliers and purchasing items required of the purchaser, together with the storage / consumption and price unit as well as various parameters for controlling the procurement and the technical specifications.

- Management of all different order types such as blanket orders, individual orders, manual and automated order requests

- Detailed price sheet function with price conditions such as quantity and discount scales and delivery conditions as well as metal price lists

- Material requirements, purchased parts and external services are automatically generated for a order-related scheduling run, a cumulated weekly quantity or can be entered manually.

- Taking into account available stocks of the minimum stock requirements, order lot sizes, replenishment times, and orders that have already been triggered.

- Early overview of the demand, to optimize the order quantities from a cost and liquidity perspective.

- Integrated dunning for suppliers

![[Translate to English:] Materialwirtschaft](/fileadmin/rguwebfiles/sitepics/icons%20Packages/package08MAS_default_48.png)

Materials Management

Materials management is the solution for efficient warehouse management for all products and precursor products, purchasing and storage materials, including load carriers, containers, pallets etc. with different inventory accounts.

- Plants, locations, storage facilities, external service providers, consignment stock, interim storage, shipping warehouse

- Inbound and Outbound Postings, inventory valuation and stock assessment derived from production notifications

- Evaluation of semi-finished and finished stocks

- Item management, items can be kept in inventory via key and batch numbers

- Permanent inventory on operating sequence balance sheet

- Various valuation methods for inventory

![[Translate to English:] Vertrieb](/fileadmin/rguwebfiles/sitepics/icons%20Packages/package12VER_default_48.png)

Distribution

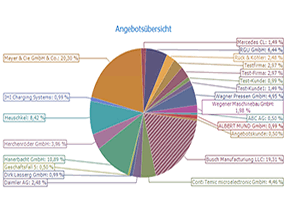

Distribution guarantees a reliable and clear quotation, order processing, shipping organization and billing.

- In just a few steps from the request to the offer. Support for all types of orders, such as sample and initial sample, single, series and call orders for products, as well as patterns and tools

- Deposit of all customer agreements, various material inflation supplement and energy inflation supplement models, all metal price lists with all columns and associated values (stock keeping unit, consumption deviation etc.). All surcharges can be specified according to customer, part, material or process.

- Easy conversion of surcharges and automatic information of the customer of price changes.

- Illustration of different logistics principles such as preview, firm order, consignment stock or merchandise

- Seamless interaction with the production and control planning: Fast confirmation of customer requested dates.

![[Translate to English:] Produktplanung](/fileadmin/rguwebfiles/sitepics/icons%20Packages/package02PLA_default_48.png)

Production Planning

Integrated Resource Plan: Unlike other systems, FRP does not separate work schedules from the bill of materials, but instead follows the way of working within the foundry. All resources needed to make a particular casting are mapped within a tree structure in a multi-level resource plan. It does not matter whether it is a self-produced part (cores, patterns, melt), a purchased part (filter / feeder, sand) or if it is an operation (molding, cleaning, reworking, both internal and external). The resource plan logic is consistent in FRP.kompakt at all levels.

- Easy creation of new parts and variants

- Fast and secure calculation of all or individual levels, taking into account all costs incurred, including purchased parts and external services. All at the touch of a button

- Similarity search for already calculated articles

- calculation archive

- Management of all technical parameters in the part master

- Integrated, extensive material database with storable inspection plans

![[Translate to English:] Materialwirtschaft](/fileadmin/rguwebfiles/sitepics/icons%20Packages/package04PPS_default_48.png)

Production Control

The production control system is the appropriate instrument for the operational and strategic planning of your production. The production control system quickly and reliably manages and controls the scheduling and capacity situations over the short and long term across all scheduling levels and bottlenecks. The production control system has particular strengths in planning and synchronizing the molding, melting and casting processes. For different foundry types different continuous and discontinuous processes have to be synchronized and availability and capacities have to be checked:

- Tool availability, preparation and provision of tools in large casting, as well as mold box and pit availability

- Coordination of molding and core production, if applicable, taking into account the model plate, core box assignment and core box combination, the provision of liquid melt for several molding areas and material qualities and if necessary the formation of casting batches

- Consideration of necessary cooling and holding times

- Passing and utilization in the post-treatment, possibly with external services

- Formation of heat treatment batches

- Integrated detailed planning with filter function

- Easy establishment of useful feedback chains for complete traceability

- Providing information to the workers through an integrated foundry information system with checklist function, especially for critical work steps

The production control system covers the needs of all foundry types, both the typical mass producer and the custom manufacturer. The currently valid production plans can be accessed online or be transferred to the plant control systems, for example, of molding plants, for operational control in the control room.

![[Translate to English:] Werkzeuge](/fileadmin/rguwebfiles/sitepics/icons%20Packages/package09MOD_default_48.png)

Pattern Management

- Pattern management includes all tools and their variants, required in the production (die casting tools, model plates, core tools, molds, CNC tools, test equipment, etc.)

- Mapping of complex model structures and all technical parameters in the resource plan (with pattern bill of material and tool card).

- Monitoring of tool life, moulding numbers and maintenance intervals Storage of all tool operations (set-up times, repair, provision, cleaning, shipping, etc.), checking of tool availability (moulding is exceeded during production, tool is in repair, etc.)

- Capture complete lifespan reports , deposit documents (drawings, photos, office files)

- tool payback

- Release procedures / blocking procedures

![[Translate to English:] Qulitätsmgmt.](/fileadmin/rguwebfiles/sitepics/icons%20Packages/package06GUE_default_48.png)

Quality Management

- Material-related parts tests

- Part-related tests (add on)

- Comprehensive inspection plan possibilities

- Spectrometer connection

- Test order tracking

- Automatic certificate generation

- Release procedure / blocking procedure

![[Translate to English:] Serviveplanung (Add on)](/fileadmin/rguwebfiles/sitepics/icons%20Packages/package13SPL_default_48.png)

Service Planning (Add on)

- Device maintenance and repair management

- On-time compliance with accident prevention regulations and other test regulations

- Maintenance interval control

- Manage internal / external services

![[Translate to English:] Schmelze (Add on)](/fileadmin/rguwebfiles/sitepics/icons%20Packages/package10GIE_default_48.png)

FRP.melt (Add on)

- Charge calculation

- Adjustment calculation

- Use of materials bill

- Melting calculation

- Melting optimization

- and much more.

We know that choosing a FRP system is a complex process that has many individual aspects to consider.

We would be happy to introduce you to our products and services in a personal and non-binding way so that you can get an idea of the performance of our solutions yourself.