The use of the latest technologies in software development opens up innovative possibilities in process optimization. With our product FRP.OPTI we offer you a holistic solution for mapping and optimizing your business processes and structures.

Workflows and processes are put to the test during the introduction of our FRP system and optimized if necessary. Our consultants are here to help you with words and deeds. The collection effort and redundant work accounts for or significantly reduces and thus also the search effort. The time savings thus gained represent a competitive advantage that allows faster, more flexible companies to pass slower competitors.

Complete, reliable and up-to-date figures from different business areas allow for flexible and meaningful reports, and this also across departments. Instead of the time-consuming, manual Excel reports with their many error risks, FRP.OPTI automatically delivers reports with reliable real-time data.

Based on FRP.OPTI technology, FRP.kompakt provides you with a powerful, pre-configured system that is modular in design and primarily aimed at small and medium sized foundries (SMEs). All modules access a uniform database and thus network the different company divisions. Whether inventory management and warehousing, sales and service, accounting and project management, all areas can call relevant data from the other areas. You benefit from consistent, complete and up-to-date information.

With our FRP.kompakt system, all your company processes become visible in an orderly manner. By understanding the cost and clarity of your business metrics, you can better understand your business and its success. This increases your planning security and facilitates project controlling.

FRP.kompakt consolidates our developments in a preconfigured standard solution. Thereby a functional range of our product FRP.OPTI adapted to the company size is available. Modules and functions can be easily selected and configured via function lists. Especially for smaller foundries FRP.kompakt offers process reliability and knowledge retention - at a reasonable price with a short introduction time. FRP.kompakt leaves room for continuous improvement processes and remains infinitely scalable after its introduction.

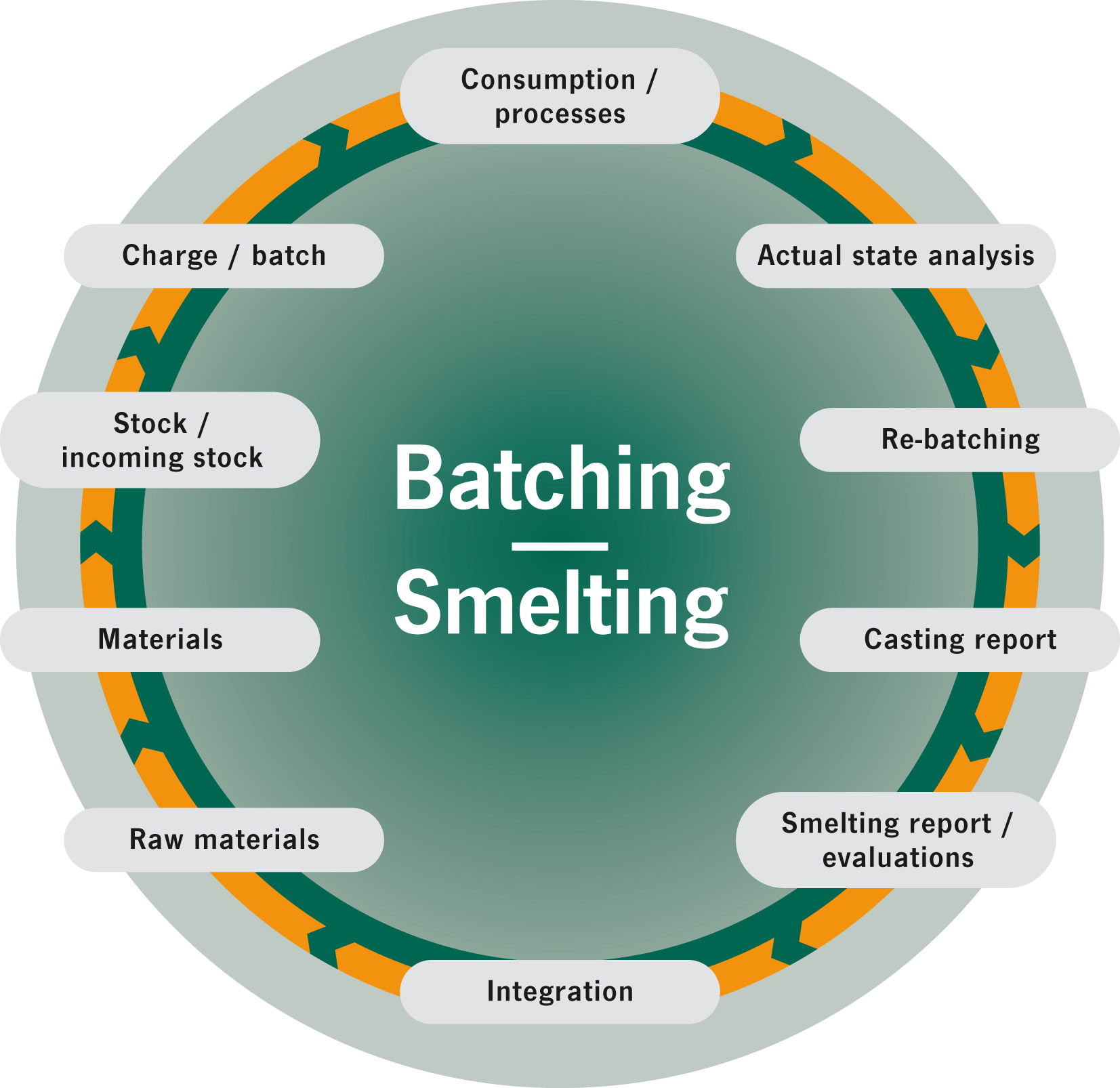

An optimal melting process combined with the most cost-effective use of materials, the reduction of re-alloying quantities and steps as well as a short melting time decide on the efficiency of the melting operation. An efficient support of the melting process combined with a functioning materials management and a successful energy management are increasingly becoming a success factor. Our product FRP.melt assists you in raising the potential and improving the melting process.

FRP.melt can be used both as a stand alone solution and integrated into our FRP.OPTI, FRP.kompakt products. A connection to external systems is optional. In contrast to other solutions on the market, our product goes far beyond the usual scope of functions of the generic invoice and, as a fine planning tool, places the melting shop and the furnace operator at the center of consideration. Just focused on the essentials without losing sight of the whole.

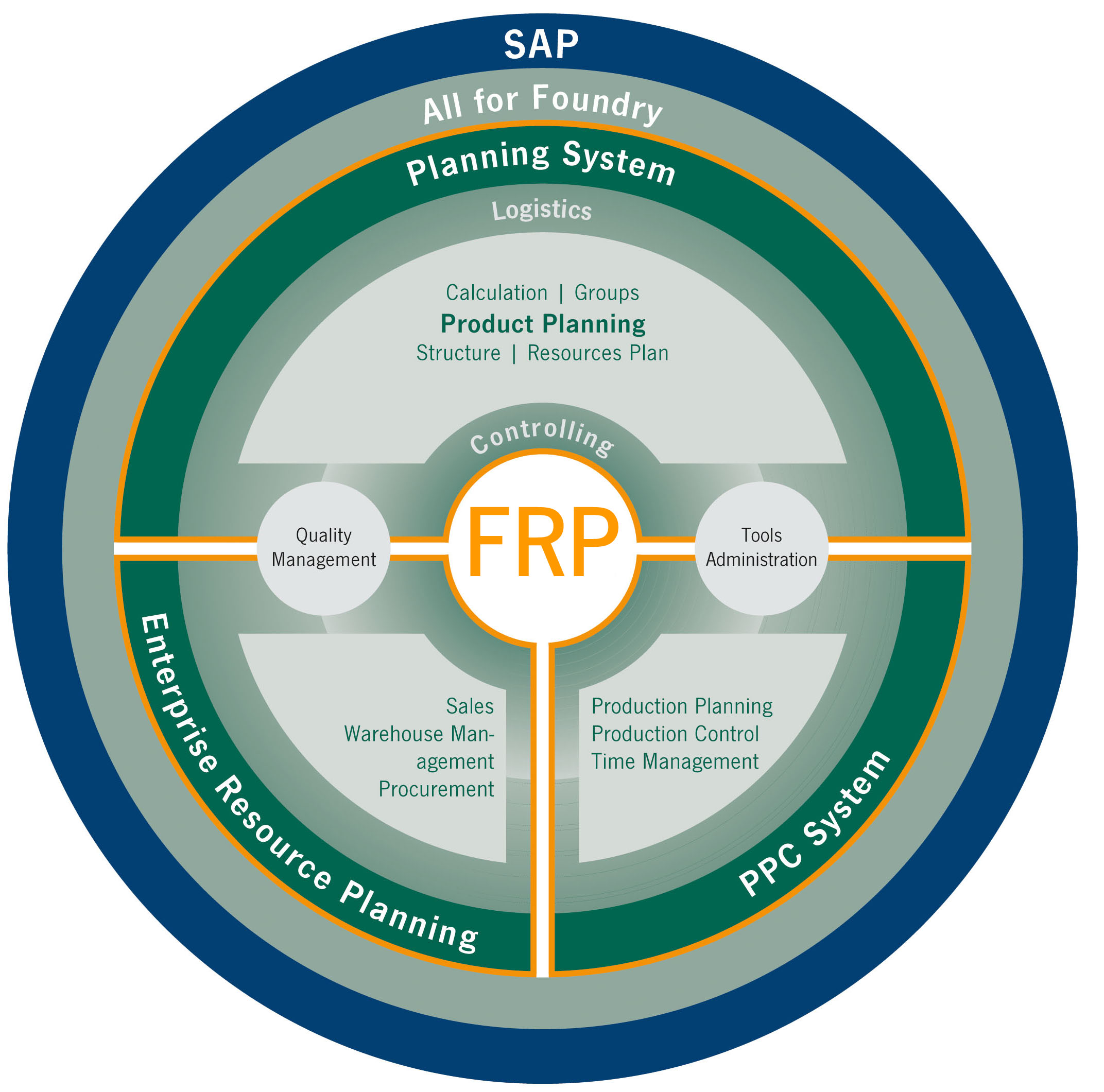

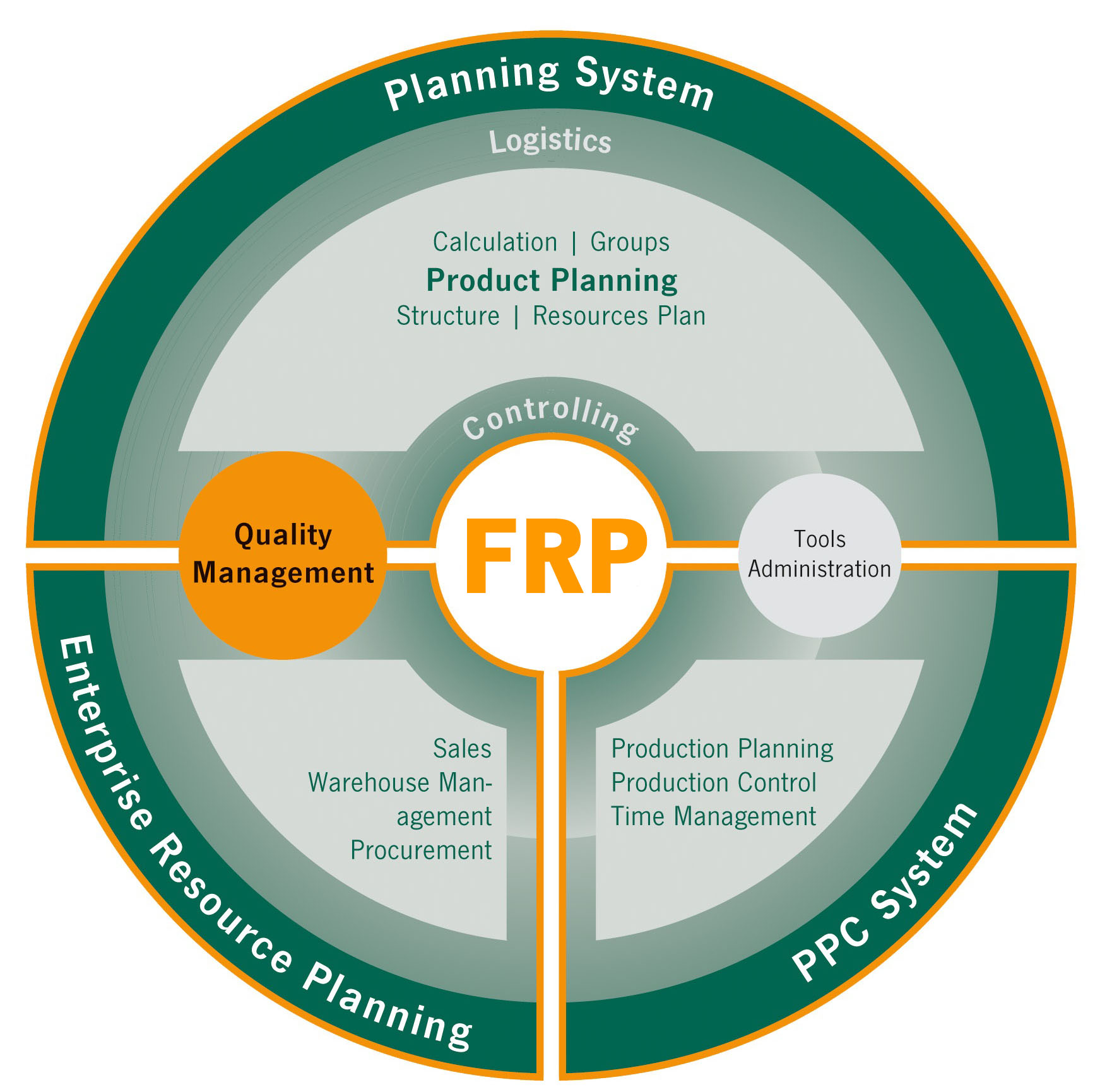

SAP is the world's leading ERP system that provides end-to-end IT support to business processes such as sales, manufacturing, materials, finance, controlling, human resources, and research / development and marketing.

MES / PPS systems - the process-oriented production management systems - can not be used as a link between the ERP system of the company management level and the actual production process. The introduction can only be successful if process and company-specific requirements are taken into account. This applies in a special way to the foundry industry. With our FRP.SAP solution, we meet these requirements and have already proved their successful use several times.

The diversity and diversity of manufacturing processes in foundries is characterized by the combination of continuous and discontinuous processes, which require a special planning system in scheduling and production planning. Our integration solution FRP.SAP combines the strengths of both systems:

- the consistent flow of quantities and values in the leading SAP system, especially in the commercial areas and controlling

- the most comprehensive MES / PPS solution for foundries for all production and process related tasks.